DC-DC Power Module and Thermal Design Design of reasonable EMC peripheral circuits | Aahhesionpower.com

1,DC-DC Power Module Thermal Design

The DC-DC Power Module heat dissipation is mainly through natural convection, forced air cooling, heat-sink installation methods or several combinations of them. For DC-DC Converters with small power below 40W, the natural heat dissipation is mainly considered in the design. In use the installation environment is mainly considered. To make it have the convection space, there is a certain power derating, and detect the case temperature at the actual maximum ambient temperature.

For DC-DC Converters above 40W or with radiator mounting holes, forced air cooling or radiator installation must be considered. The basic method is to calculate the dissipated power Pd=Pout / -Pout of DC-DC Power Module through efficiencyη , calculate the case temperatureθc-a=(Tc-Ta)/Pd through the maximum shell temperature T c and the required working environment temperature Ta, and select the appropriate heat sink or wind speed according to the calculated heat resistance. The calculation is only the first step to consider the heat dissipation, and due to many external environmental factors, the case temperature must be verified after selecting the heat sink and the wind speed for further correction.

2,Design of reasonable EMC peripheral circuits

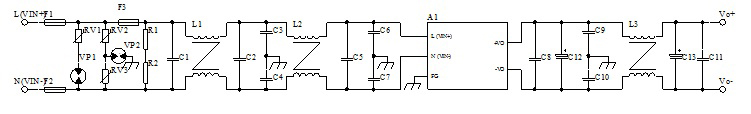

Use the recommended reference circuit 1, which has good lightning protection properties.

FIG. 10 recommended reference to circuit 1

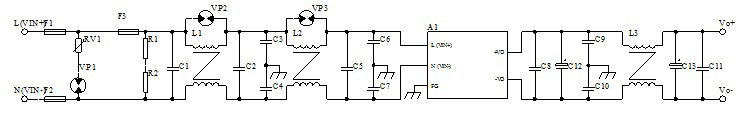

At present, more and more products require that the input to Ground is not only to meet the high isolation, but also to meet the high common mode surge, and do not allow surge protective devices between the input and Ground. At this point, the recommended reference circuit 2 is a good option.

FIG. 11 recommended reference to circuit 2

评论

发表评论