Aubibrush: Guide to Choosing Nylon Brush Roller for Your Project

Are you working on a project that requires a nylon brush roller? Then you've come to the right place. In this comprehensive guide, we will walk you through everything you need to know about choosing the perfect nylon brush roller for your specific project.

Don't let the overwhelming number of options on the market confuse you. With this guide, you will gain the confidence to choose the ideal nylon brush roller that meets your needs and helps you achieve outstanding results. So let's get started!

Advantages of Using Nylon Brush Rollers

Nylon brush rollers offer several advantages that make them a popular choice for various applications.

Firstly, nylon bristles are durable and resistant to wear and tear, ensuring a longer lifespan compared to other materials. This makes them ideal for heavy-duty projects where the brush roller needs to withstand frequent use and tough conditions.

Additionally, nylon bristles have excellent flexibility, allowing them to adapt to different surfaces and contours. This versatility makes nylon brush rollers suitable for a wide range of applications, including cleaning, polishing, deburring, and surface preparation. Whether you need to remove dirt and debris, smooth rough surfaces, or apply finishes, nylon brush rollers can get the job done efficiently.

Another notable advantage of nylon brush rollers is their ability to handle various chemicals and solvents. Nylon is resistant to many common chemicals, making it a reliable choice for projects that involve cleaning agents or other substances that could potentially damage other types of brush rollers.

Common Applications of Nylon Brush Rollers

Nylon brush rollers find applications in numerous industries and projects. Let's explore some common scenarios where nylon brush rollers are widely used.

- Industrial Cleaning

Nylon brush rollers are commonly employed in industrial cleaning applications such as conveyor belt cleaning, part washing, and surface preparation. T - Woodworking

In the woodworking industry, nylon brush rollers are utilized for sanding, finishing, and surface preparation. - Printing

Nylon brush rollers play a vital role in the printing industry, particularly in the cleaning and maintenance of printing presses. - Food Processing

Nylon brush rollers are widely used in the food processing industry for tasks such as fruit and vegetable washing, conveyor belt cleaning, and general equipment maintenance. The chemical resistance of nylon bristles makes them suitable for use with cleaning agents and sanitizers, ensuring a hygienic production environment.

These are just a few examples of the many applications of nylon brush rollers. From automotive manufacturing to metal fabrication, there are countless industries and projects where nylon brush rollers prove to be invaluable tools.

Factors to consider when choosing a nylon brush roller

When selecting a nylon brush roller for your project, it's important to consider several factors to ensure you choose the most suitable option. Let's explore these factors in detail.

- Bristle Type

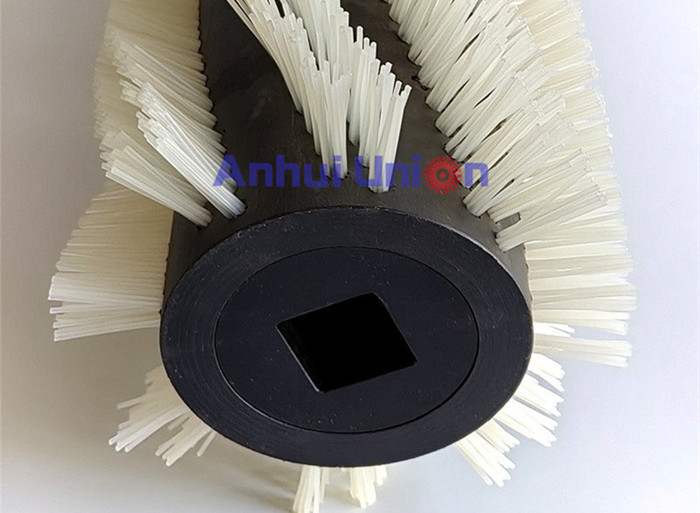

Nylon brush rollers come in different bristle types, each offering specific properties and benefits. Some common bristle types include abrasive nylon, flagged nylon, and crimped nylon. Abrasive nylon bristles are ideal for applications that require more aggressive cleaning or deburring. Flagged nylon bristles are softer and work well for fine cleaning and surface finishing. Crimped nylon bristles provide a balanced approach suitable for a variety of tasks. Consider your project requirements and select the bristle type that aligns with your needs. - Brush Roller Configuration

Nylon brush rollers can have different configurations, including spiral, helical, and straight. Spiral configurations provide uniform brushing action and are suitable for general cleaning and surface preparation. Helical configurations excel in heavy-duty applications, offering enhanced cutting and deburring performance. Straight configurations are often used for light-duty cleaning and finishing tasks. Understanding the different configurations will help you choose the one that best suits your project requirements. - Size and Diameter

The size and diameter of the nylon brush roller should be chosen based on the specific application and the surface to be worked on. A larger diameter brush roller covers more surface area, allowing for faster work progress. However, a smaller diameter brush roller may be necessary for intricate or hard-to-reach areas. Consider the dimensions of your project and select the appropriate size and diameter accordingly. - Speed and Rotation

The speed and rotation of the brush roller can also impact its performance. Higher speeds are generally suitable for aggressive cleaning or material removal, while slower speeds are more appropriate for delicate or precision tasks. Additionally, some brush rollers offer reversible rotation, allowing for versatile use. Evaluate the speed and rotation options available and choose the one that best matches your project needs. - Mounting Options

Consider the mounting options available for the nylon brush roller. Different projects may require specific mounting configurations, such as shaft-mounted, arbor-mounted, or core-mounted brush rollers. Ensure that the mounting option of the brush roller you choose is compatible with your equipment or setup.

By considering these factors, you can narrow down your options and choose a nylon brush roller that is perfectly suited for your project requirements.

With the knowledge gained from this guide, you are now equipped to choose the perfect nylon brush roller that aligns with your preferences and project needs.

评论

发表评论