The use of electrolytic polishing of stainless steel | Xmystool.com

Electrolytic polishing has become a key surface treatment technology in the semiconductor, optoelectronic, biochemical, medical, instrument, kitchen, and food industries.

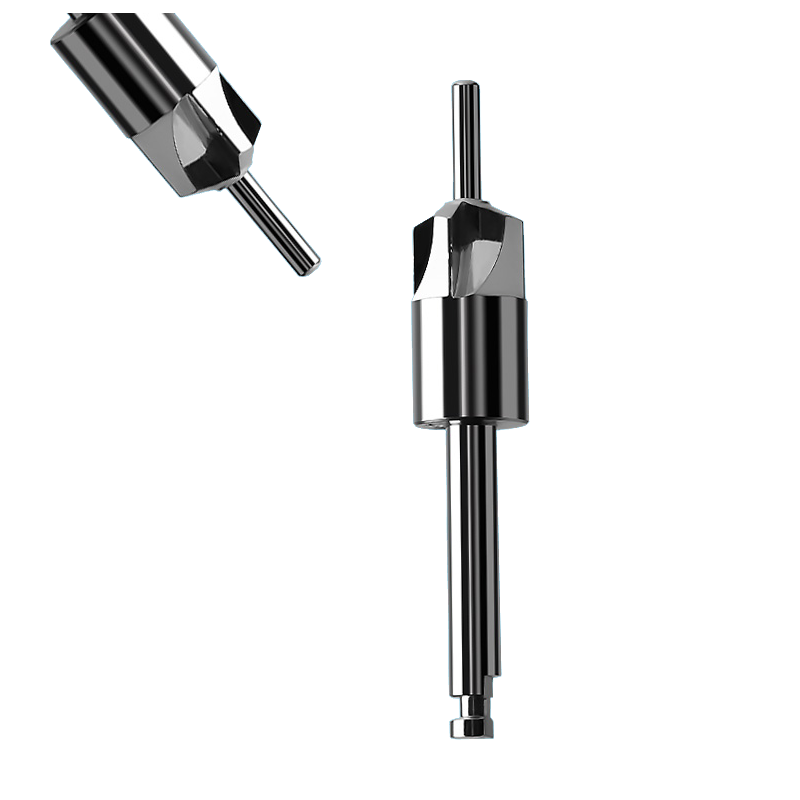

Hang the stainless steel or aluminum alloy workpiece on the anode and immerse it in a special electrolyte to energize it. The surface of the workpiece is smooth and shiny due to electrochemical dissolution. This method is called electrolytic polishing.

High cleanliness-remove oxides on the surface of stainless steel to obtain a smooth and clean surface. Removal of burrs-suitable for areas that are difficult to reach by precision components and mechanical processing. Precision machining-can accurately correct the size of the workpiece and reduce the surface roughness.

Xiamen Yushang is a professional supplier in China with 10 years experience devoted to producing kinds of dental tools,accept custom service,OEM/ODM are welcome.If you have any sample or drawing,can contact sales02@ysgjtool.com to get the prices.

评论

发表评论