What is End mill?

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, most milling bits can cut in the radial direction.

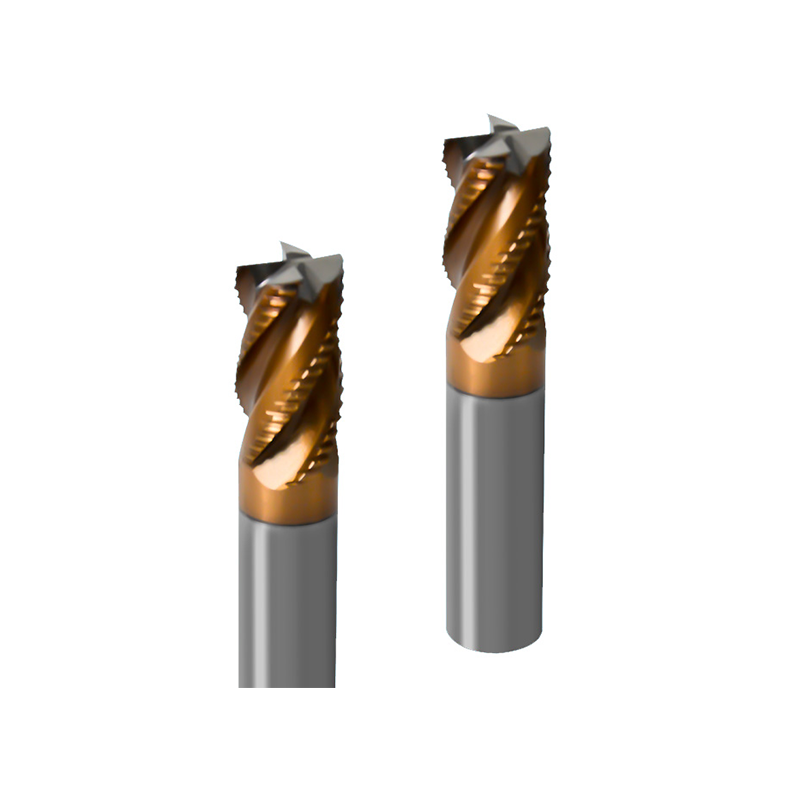

End mills feature rugged carbide substrates and multi-layered coatings for improved cutting action and longer tool life. The Solid Carbide End Mill is configured for different radius filleting. Available with two, three, and four flutes, it also features a cylindrical shank DIN 6535 HA. High Feed End Mill is designed for high feed rates with shallow cutting depths for a wide range of materials up to 56 HRC.

Redesigned to offer the rigidity, chip control and tool life to achieve the lowest possible cost per metre machined in steels, stainless steels, cast iron, titanium and some aluminium grades, these solid end mills provide excellent process reliability across a broad application range.

End mills are typically made on CNC (computer numeric controlled) tool and cutter grinder machines under high-pressure lubricants such as water, water-soluble oil, and high-flashpoint oil. Grinding inside the machine is accomplished with abrasive wheels mounted on a spindle (and in some cases, multiple spindles). Depending on what material is being ground, these wheels are made with industrial diamond (when grinding tungsten carbide), cubic boron nitride (when grinding cobalt steel), and other materials (when grinding, for instance, ceramics), set in a bond.

Yushang is a professional supplier with more than 10 years' experience in CNC tools, medical instruments and dental implant tools. Also accept custom according to sample or drawing, contact sales01@ysgjtool.com to get more information.

评论

发表评论