Variable Geometry/Nozzle TURBO | Refoneturbo.com

In the last 20 years, Turbocharging has become generally used as a methods to increase auto engine power.

A typical Turbocharger is made up of a compressor wheel and a turbine wheel installed on the same shaft. The exhaust gas expelled from the cylinder spins the turbine,which drives the compressor wheel. This Turbo sucks and compresses the surrounding air, then forces the much denser air into the intake manifold.

If the turbocharger is spinning too fast, the pressure in the intake manifold becomes very high and can eventually damage the engine.

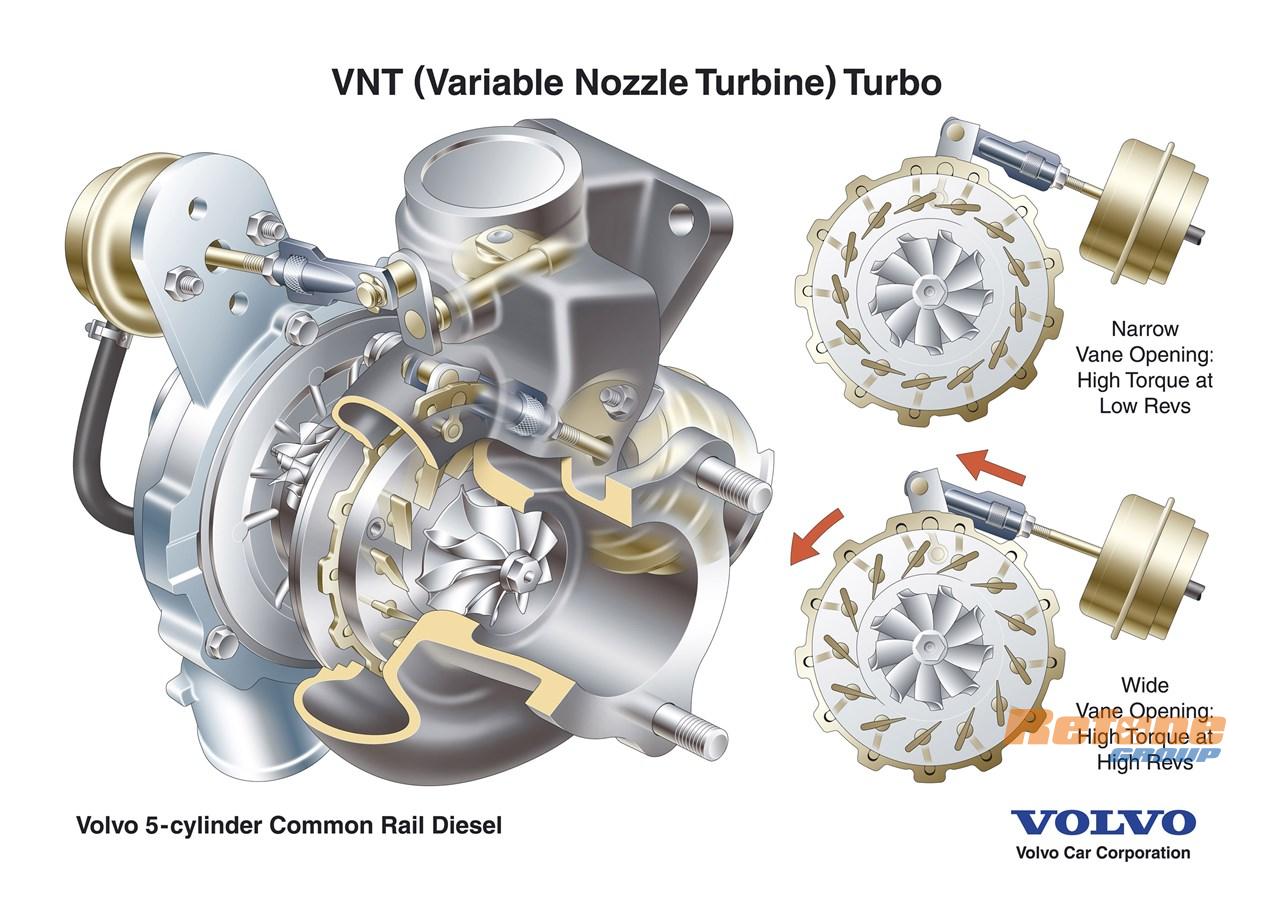

Variable nozzle Turbos are equipped with a set of adjustable guide vanes positioned on the turbine stator. By changing the angle of the vanes, the turbine flow area and the angle at which the exhaust gas is directed at the turbine blades can be adapted in order to allow an optimum turbocharger operation over a large range of engine speeds.

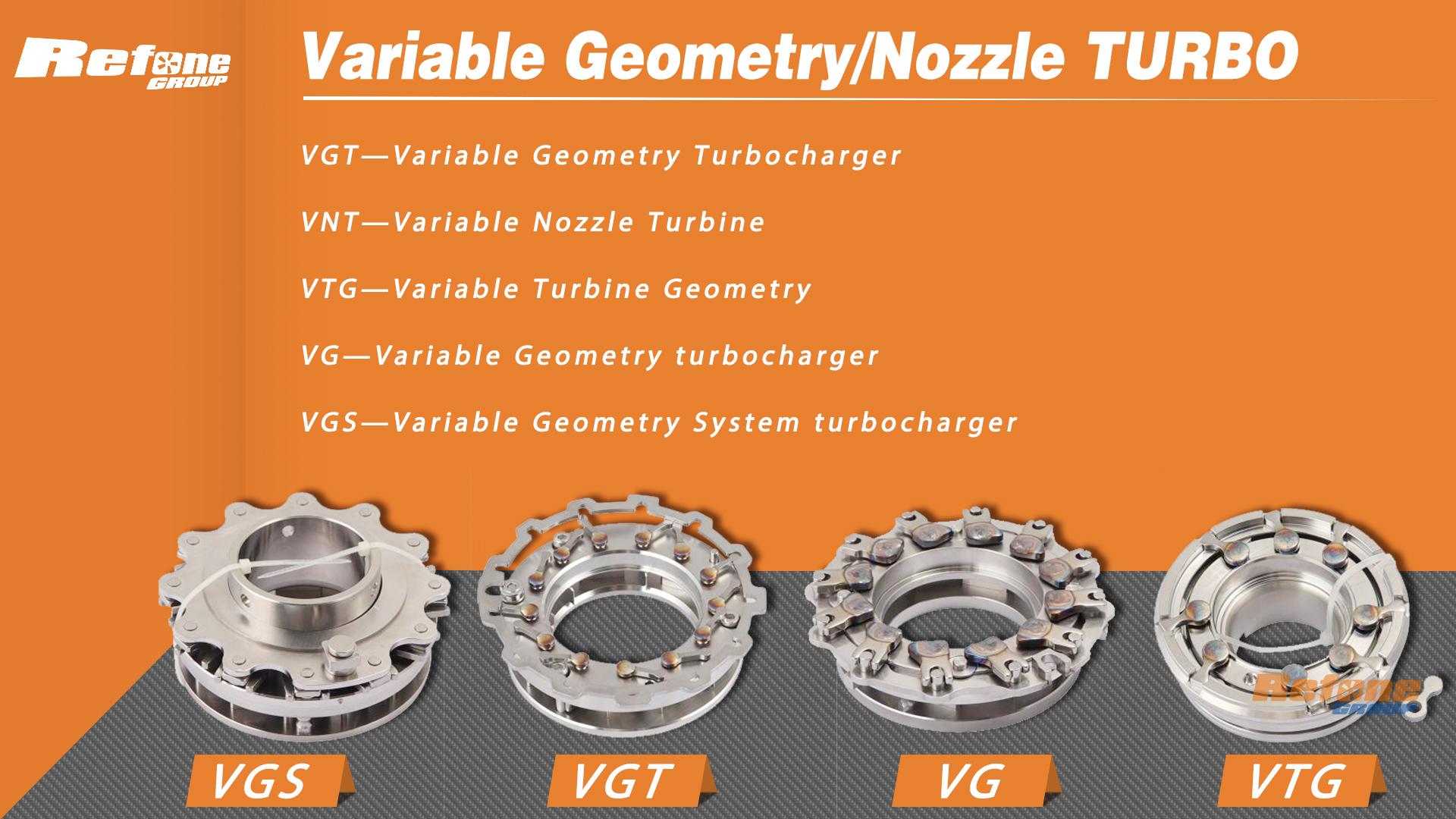

There are many different acronyms that are commonly used when referring to turbochargers with variable geometry turbines. In most cases these are or have been trademarks that a particular manufacturer has used with reference to their product. Nowadays, they are more widely used in the original and after-sale turbocharger market. Some are as following:

VGT— Variable Geometry Turbocharger

VNT— Variable Nozzle Turbine

VTG—Variable Turbine Geometry

VG—Variable Geometry turbocharger

VGS—Variable Geometry System turbocharger

In many designs, a variable geometry turbine does not include a bypass valve, so the turbine must be capable of handling all of the exhaust flow from the engine while avoiding overboost and overspeeding the turbocharger.

Compared to a fixed geometry turbine, the variable geometry turbine allows significant flexibility over the pressure ratio/flow relationship across the turbine and by extension, the engine ΔP. This flexibility can be used for improving low speed torque characteristics, reducing turbocharger lag and in diesel engines, driving EGR flow.

评论

发表评论